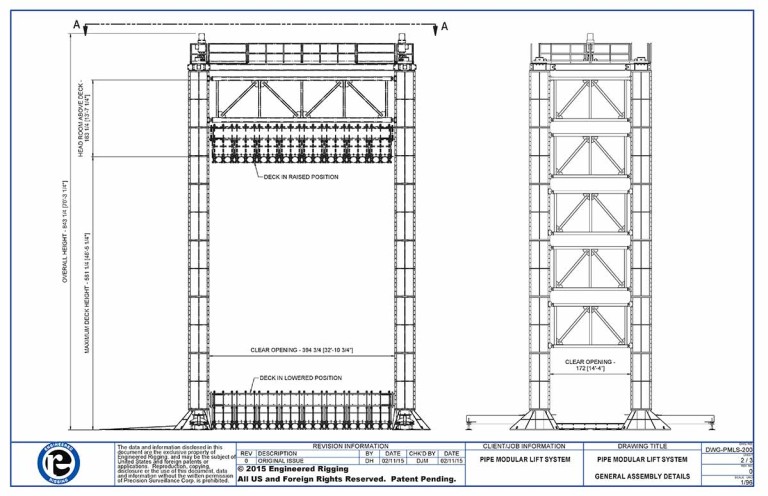

PIPE MODULAR LIFT SYSTEM

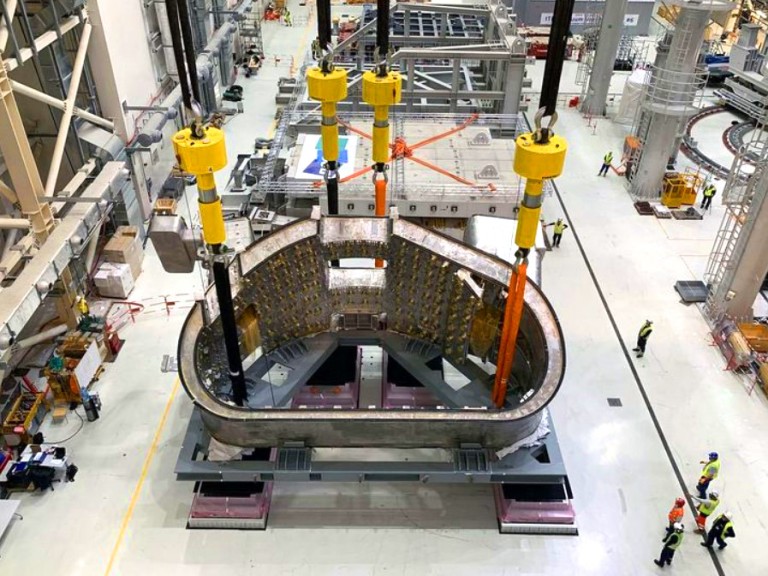

Engineered Rigging’s patent-pending Pipe Modular Lift Systems (PMLS) eliminates the hazards of suspended loads. Different from all other heavy lifting systems, the PMLS employs a platform that mechanically raises and lowers heavy cargo via a system of vertical lift rods connected through gearboxes to electric motors. The heavy-walled steel lift secures both the cargo and platform, providing positive mechanical engagement 100% of the time.

- Modular Design: Customizable lift capacity, height and footprint

- Faster Lift Times: 20 inches per minute

- Superior Reliability: No failing cable drums or leaking hydraulics.

- High Wind Tolerance: Keeps critical path projects on schedule.

- Easy to Transport: Ships in standard ground trailers–no wide load or heavy load permits needed.

- Rapid Assembly: Fully operational in just 5 shifts.

- Proudly made in the USA.

Safe, Seamless Operation

The PMLS is designed to accept any mobile material handling equipment, such as an SPMT or intermodal transport, with the cargo in place. Once the PMLS reaches the desired elevation, the cargo can be transferred from the lift platform to the adjoining structure which minimizes load handling and eliminates the need for additional equipment. The PMLS is the safest and fastest method of lifting equipment and materials up and into an elevated equipment hatch—about twice as fast as comparable strand jack systems!

- Perfectly synchronized lifting

- Load fully secured, not suspended

- Self-locking, no cribbing required

- Unaffected by unbalanced loads

- Power failsafe ensures load remains in place on the secured platform until power is restored.

- Stable in harsh environmental conditions

- Remote controllable up to 350 feet

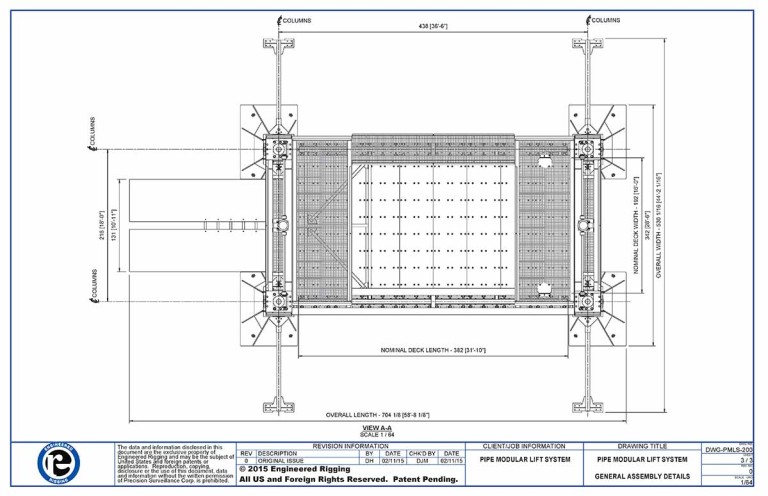

Powerful, Modular Design

The PMLS can be customized to your capacity requirements and the project footprint.

Lift Speed

20 inches per minute

Lift Capacity

400 to 1,200 tons

Height

Configurable in 10-foot increments

Span Openings

50 feet or larger

Layout

Square, rectangular or round

Wind Load

50 mph (operating)

120 mph (stationary)

Side Load

5%

Power Requirements

80V-3P

PMLS Spec Sheets

Click to enlarge the document.

Industry Standards Compliance

Engineered Rigging’s Pipe Modular Lift System complies with the applications sections of the following standards:

- AISC Manual of Steel Construction, 9th Ed. and 13th Ed.

- ASCE 7–10, Minimum Design Loads for Buildings and Other Structures

- AWS D1.1, Structural Welding Code

- ASME NQA-1-2004, Subpart 2.15, Quality Assurance Requirements for Nuclear Facility Applications

- ASME B30, Various Sections

- NUREG 0612, Control of Heavy Loads at Nuclear Plants

- 29 CFR 1926, OSHA Construction Industry Regulations

- ANSI/SAI A92.9, Mast-Climbing Work Platforms

- ASME A120.1, Safety Requirements for Powered Platforms and Traveling Ladders and Gantries for Building Maintenance

Pipe Modular Lift System

Engineered Rigging’s patent-pending Pipe Modular Lift Systems (PMLS) eliminates the hazards of suspended loads. Different from all other heavy lifting systems, the PMLS employs a platform that mechanically raises and lowers heavy cargo via a system of vertical lift rods connected through gearboxes to electric motors. The heavy-walled steel lift secures both the cargo and platform, providing positive mechanical engagement 100% of the time.